Fast cycle times

The distinctive feature of SPRINT turning centers is the functional layout of the work area, combined with driven tools and a Y-axis on the main spindle. Thanks to the counter spindle, which is standard in every machine of the SPRINT series, it's possible to achieve fast cycle times in completely automatic production.

Dmg Mori Youtube Channel

The NZX and NZX-S series form the youngest generation of DMG MORI production turning machines. Every series sets new standards regarding quality, safety and economic viability when it comes to manufacturing highly precise rotating parts in average to large numbers. DMGMori UK can't apply for a loan with DMG Mori Germany or USA or Japan etc. To make things 'Right'. So necessarily for a big expensive machine the customer most likely will bear the brunt in larger fraction of having a machine through bad 'Orchestration' of many elements resulting in a 'BAD' machine. Share your videos with friends, family, and the world. – DMG MORI celebrates the trends and innovations as well as innovative products and solutions with virtual live presentations and a digital showroom a class of its own at the DMG MORI DIGITAL EVENT.

Small but easy to set-up

Featuring the smallest footprints on the market, but thanks to the wide work area, SPRINT machines are comfortable to set-up since every tool position is easily accessible and the SWISSTYPEkit can be changed in less than 30 minutes.

Davis Manufacturing

Youtube Dmg Mori Download

Youtube Dmg Mori Full

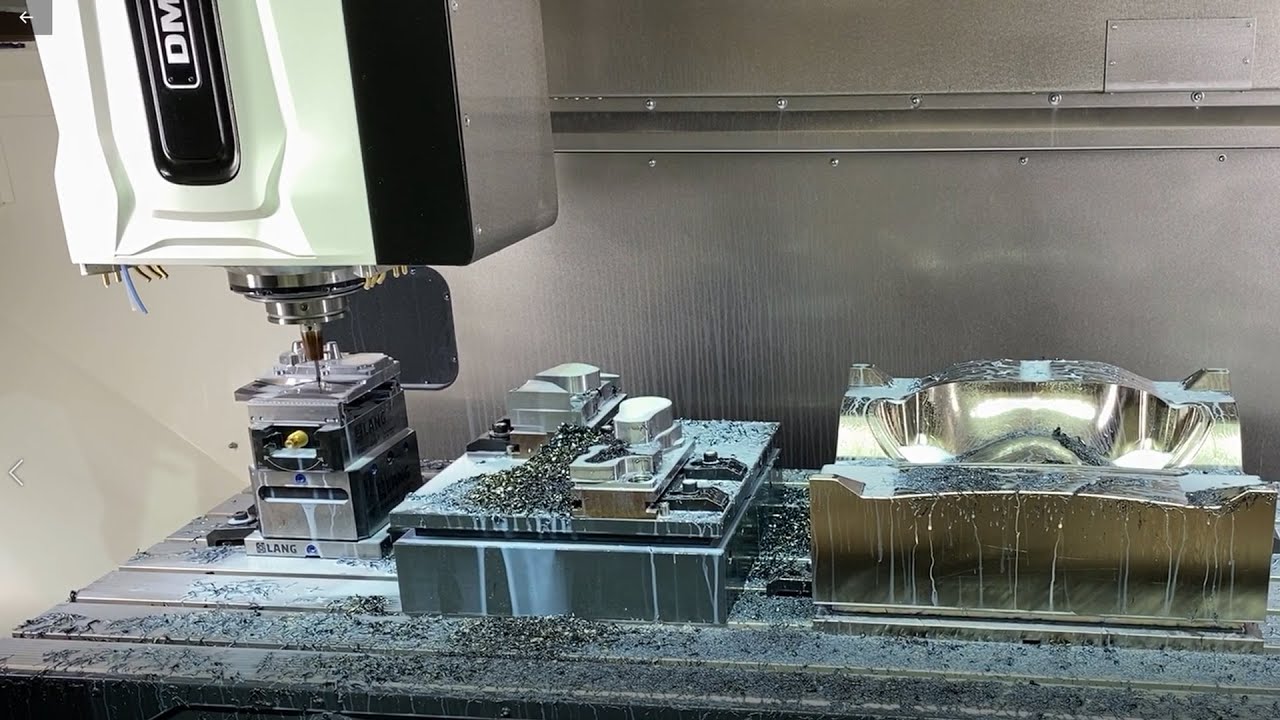

DMG MORI is proud of its manufacturing capabilities in the United States.

Our Davis, California campus consists of both our U.S. factory and DMG MORI’s American Research and Development hub, which allows us to be closer to our North American customers. The extensive use of automation combined with our highly skilled workforce make Davis one of the most advanced factories in the world.

Youtube Dmg Mori

As one of our valued customers, you will have the opportunity to see how our machines are built from the ground up. Take a closer look at our machining, quality assurance, assembly processes, and a fierce belief in utilizing our own machines and automation systems as an integral part of our factory. The DMC 340 U, three NHX 10000’s, and two NH 6300 DCGII, each with pallet pool systems and automation, have been built using our own products. Our fully-automated line also includes robot loaders and washing stations custom-built into our LPP systems.